Effective sealing for low speed rotating applications in construction and excavation equipment.

Trelleborg is synonymous with innovation. Proof of this is the Nexus face seal, an alternative to mechanical face seals that provides longer service life. It provides a lightweight, flexible barrier against external dirt and mud compression in slow rotating applications, such as the excavators for which it was originally developed. It can also improve the longevity and total cost of ownership of gearboxes, undercarriages and axles in almost any construction or mining machinery.

Mechanical face seals are specifically designed for rotating applications in extremely harsh environments, where they withstand severe wear and prevent the ingress of abrasive and aggressive external media.

Main advantages

- Thanks to its innovative cold stamping process and new material technology, it is more cost-effective than competitive products in large volumes.

- High sealing performance at low peripheral speeds, such as those encountered in construction machinery and in tunneling, drilling and mining operations.

- Good flexibility against mud compression for long-lasting performance on construction sites and excavations

Mud compression

In heavily contaminated environments, sludge can compress between the casing and seal, creating pressure that reduces efficiency and causes failure.

Nexus Face Seal has greater flexibility to manage the effects of slurry compression, extending service life, particularly for vehicles operating in aggressive and viscous slurries found on construction sites.

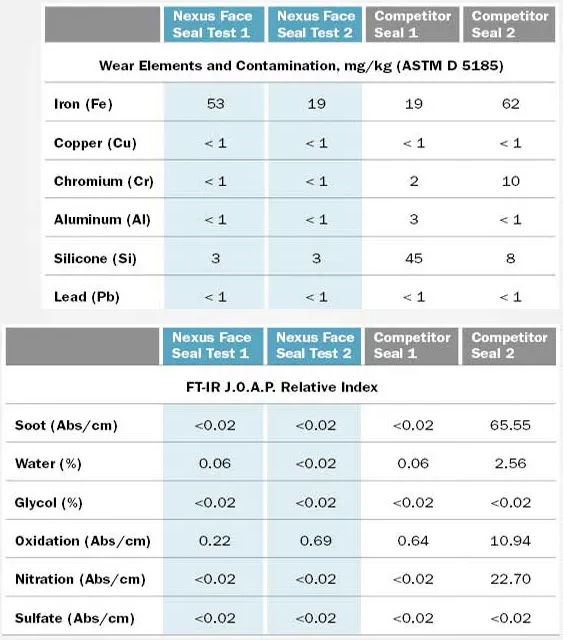

Oil contamination

In heavily contaminated environments, sludge can compress between the casing and seal, creating pressure that reduces efficiency and causes failure.

Nexus Face Seal has greater flexibility to manage the effects of slurry compression, extending service life, particularly for vehicles operating in aggressive and viscous slurries found on construction sites.

Peripheral speed Up to 1.5 m/s

Temperature Up to +200 °C depending on the O-ring material (as on the previous page)

Differential pressure Up to 3 bar as differential pressure

Outside diameter From 50 mm to 460 mm